Property Profile |

|

|---|---|

| Location | Residential |

| City | Old Saybrook, Connecticut |

The innovative combination of an energy-saving wall-hung boiler,

two condensing tankless water heaters and the mechanical skills of contractor Chuck Appleby delivers the lifestyle a customer wants without shrinking the livable space in her home.

BY RAYMOND RASALAN

OLD SAYBROOK, CONN. — Inventiveness is the economic engine of entrepreneurs. The quest to devise better ways and new solutions propels many a small business in this country, and Appleby Plumbing owner Chuck Appleby is no exception. This Old Saybrook, Conn., contractor has built a loyal and growing client base by researching new products that solve real problems for homeowners in this coastal region.

At Appleby Plumbing, innovative solutions often stem from customer location; specifically, the fact that most its population lives in a flood plain. This geographic reality limits installation options for nearly every mechanical device, which often means homeowners must sacrifice living or storage space for space-heating and water-heating equipment. Many more regions along coastal zones soon will have to contend with similar constraints, as the Federal Emergency Management Agency (FEMA) rewrites rules. Following active storm years that saw unprecedented rain and flooding, Appleby says the new rules will raise height requirements for both structures and mechanical equipment.

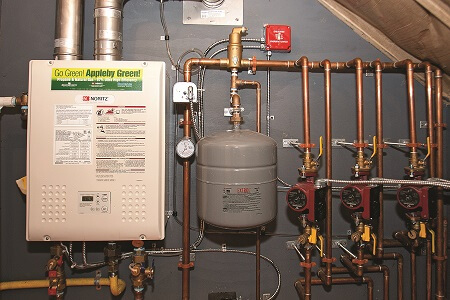

Appleby recently created a very different, but highly satisfactory home-heating solution for customer Sharon Baker by combining two innovative products – a wall-hung hydronic boiler and a pair of high-efficiency condensing tankless water heaters – in a high-and-dry, flood-proof installation arrangement that delivered the comfort Baker wanted without sacrificing any usable space in her new, three-bedroom home.

Sharon Baker Residence

Factory-built home: Engineering the mechanical systems and scheduling the installation for a new home usually follows a rather predictable schedule. With the Baker residence, however, familiar went out the window. Rather than the traditional site-built construction, Baker contracted with a modular-home company to have Baker’s new residence constructed in their Pennsylvania factory, delivered to the lot in pre-built modules and assembled on site.

“This approach changed the schedule, but also afforded us some design freedom,” explains Appleby. “We had a choice on where to place the mechanical equipment. In looking at the plan, we realized the best option was an unused storage space up in the attic.”

This selection made the homeowner happy by preserving main-floor living and storage space in the single-story home. A garage installation plan would have extended the piping a greater distance and taken area away from full use of the garage. But the highly attractive attic strategy also created some very specific equipment constraints.

“Weight is a huge consideration in placing heating equipment in an attic, even though we are able to hang the equipment on the studs,” says Appleby. This strategy automatically eliminated cast iron boilers, as well as any boiler with a high water volume. In both cases, he notes, “the weight and leak risk are too much.”

A long-time user of Noritz tankless water heaters, Appleby was one of the first contractors nationwide to “test-drive” the company’s new wall-hung, tankless hydronic boilers. The features of the NH150-DV model seemed ready-made for Appleby’s particular needs on this installation:

- energy-efficient, with a thermal rating of 82.8 percent;

- lightweight at just under 66 pounds;

- nine different temperature settings;

- low water mass, averaging only 0.25 to 1 gallon of water inside the boiler, with a maximum flow rate of 17 gallons per minute (gpm);

- a fully modulating burner that automatically adjusts firing level according to the outdoor air temperature, with a maximum input of 155,000 Btu per hour; and

- direct vent design to draw makeup air from the outside, rather than from within the home.

In addition, the boiler package included new outdoor reset control system and a new Grundfos circulator, whose installation was “very easy and trouble-free,” according to Appleby.

With these specifications, the 24-inch x 18-inch x 9.5-inch NH150 meets the needs of Baker’s three baseboard heating zones, maintaining constant room temperatures. “Reliable heat at a reasonable cost — that is, a unit that installs and services easily — are what matter most to customers,” says Appleby. “This job just had a few more criteria, but affordable, consistent comfort was fundamental.”

Working with the modular builder during the design phase, Appleby conceived a mechanical room in the attic with pull-down stairs providing access. During construction, piping was brought to the attic, as was wiring for the controls. “This was new to the factory; they hadn’t seen this installation location for the mechanical equipment before,” says Appleby. “Most often, they carve out a closet space, but they liked this solution and intend to share it with future customers.”

The attic makes it easy for the domestic piping and hydronic heating. The possible discharge of all appliance relief valves is contained in easy-mounted, indirect waste receptors, while the traps protect the high-efficiency equipment from condensate.

NH150-DV Hydronic Boiler

NRC98-DV Tankless Water Heaters

Why two water heaters? Besides the wall-hung boiler, the attic mechanical room also houses the two, 93-percent efficient, Noritz NRC98-DV condensing tankless water heaters. “We chose to install two water heaters because of the homeowner’s large whirlpool, which is equipped with a tub filler with a 13-gpm flow rate. She wanted a continuous supply of hot water, not only to fill the whirlpool initially, but also to keep the water warm while soaking. The double-tankless setup ensures all the hot water she needs.”

Building a mechanical room in the attic involves more than simply connecting the piping and the wiring, while affixing the various equipment and accessories to the studs. Two, sometimes three Appleby mechanics spent four days outfitting the space properly and completing the installation.

Condensing tankless water heaters like the NRC98 use a secondary heat exchanger to boost efficiency an extra ten points by capturing more heat from combustion gases as they escape up the flue. This heat-absorption process, in turn, cools the flue gases enough to permit venting with less costly, and more installer-friendly PVC piping, rather than Category III Stainless Steel.

This cooling process generates a condensate that must be neutralized to comply with local plumbing codes. Appleby accomplished the task by installing the indirect waste receptors, which he also services, as needed.

To ensure that the room itself would provide the same worry-free operation as the mechanical equipment, Appleby also devised a liner to protect against piping leaks. “A watertight shower floor membrane liner with a floor drain protects the home against damage from any possible leak, a must when installing equipment in the attic,” he says. “We have complete confidence in the system — not only because we designed it, but also because of this built-in, fail-safe, watertight backup.”

Appleby describes the Baker residence as “a blueprint of sorts for a tankless boiler-water heater installation solution that meets the special needs of our locale. It highlights the simplicity with which we can install cutting-edge heating equipment in properties located in flood zones. That’s what I call innovation.”

Raymond Rasalan, a 10-year veteran of the heating and tankless water heater business, serves as new-product release coordinator specialist for Noritz America, based at the company’s Fountain Valley, Calif., headquarters. He can be reached at: (714) 433-7832; e-mail: rrasalan@noritz.com.

For editorial assistance, contact:

John O’Reilly

GreenHouse Digital + PR

T – 815.469.9100, ext. 302

E-mail – john@greenhousedigitalpr.com

# # #

NORITZ AMERICA CORPORATION, a subsidiary of Noritz Japan, has corporate offices in Fountain Valley, Calif., as well as in Dallas, Atlanta, Chicago and Hawthorne, N.Y. Offering a full line of tankless water heaters to meet the hot water demands of residential and commercial applications. Noritz supports its products with a national network of skilled representatives and employees who are committed to providing the finest products and services to our communities by helping consumers live in a more comfortable, efficient and healthy lifestyle.

For more information on Noritz America and the entire line of Noritz’s ENERGY STAR® tankless water heaters, please call (877) 986-6748 or visit our website at www.noritz.com.